Metal spinning process and technology

This article introduce the metal spinning technology and different process ways, you can know the different metal spinning forming technology after you read this article.

What is metal spinning process >>

Metal spinning process is a metal forming technology to make metal sheet or tube to form different shape that is solid of revolution on metal spinning machine.

1. Metal spinning tool

We need to design different mold and different radius of roller according to different shape of metal spun product.

1) Mold >>

Mold function is to offer the support force in the metal spinning process, the mold exterior curve is same with the interior curve of metal spun product.

2) Mold materials

Aluminum and brass, copper can use 45# without heating treatment, steel can use 40Cr or 45 with heating treatment, stainless steel need use Cr12mov with heating treatment, heating spinning can use H13. the hardness of metal Spinning material is harder, it needs hard mold material, otherwise the mold will be scratches.

3) Roller >>

Right roller can reduce the break or wrinkle situation in the metal spinning process. Usually thin sheet (T<1MM)choose the little radius (R<6MM), thick sheet (T>1.5MM) choose the big roller ( R>8MM).

4) Roller materials

CR12mov + heating treatment, the hardness of roller is higher, the exterior surface of metal spinning products is smoother.

2. Materials - spinning performance>>

Different metal has different metal spinning property and performance. At first, The ductility of metal sheet is better, the deep drawing ability of metal spinning is better. Such as aluminum can be spun easily and higer height compare to stainless steel, as aluminum have good ductility and spun performance. Second, the tensile strength of materials decides to need how many spinning force by machine at the same condition, stainless steel needs stronger spinning force than aluminum spinning. Third, The materials hardness is harder , the metal spinning process will break easily, commonly using the hot spinning to make the hard material.

How to calculate the dimension of metal spinning materials>>

3. Metal spinning thinning

Blank is thinning after roller pull and press in metal spinning forming, conventional spinning like hand spinning is less thinning, but shearing spinning in CNC spinning can make blank sheet is easier to thin. Metal spinning thinning is 10% - 40%, the cylinder of height value is more, the thinning is more, the cone angle value is litter, the thinning is more.

How to calculate the thinning rate of metal spinning materials >>

4. The different metal spinning process ways

1) Shearing and conventional spinning

The forming position that roller press the workpiece on the mold and make the sheet shear deforestation is shearing spinning, conventional spinning only roller pull the sheet without touch the mold and make the workpiece diameter reduce and height increase.

All the cone( angle >20º) is shearing spinning, cylinder metal spinning have conventional spinning and shearing spinning, shearing spinning position is roller press the work piece on the mold ( the distance between roller and mold <blank thickness ), the other positon is conventional spinning.

Shearing spinning can make refining the grain, the tensile strength of metal spinning product will inprove .

2) Cold spinning and hot spinning

Thin or soft metal blank sheet use cold spinning to make, thick or hard spinning use hot spinning to make. Cold spinning have higher precision than hot spinning, if you want to control the accuracy of hot spinning, you need to keep and the heating time to control blank temperature. The other difference is cold spinning will have smoother internal surface than hot spinning, interior materials of thick sheet flow slowly than exterior materials, so the interior surface will have fatigue lines or orange peel.

Why needs hot metal spinning : At first, hot spinning can process the hard metal sheet, such as SUS630, Hardox, Inconel 625, Inconel 718 (Nickel basse superalloy), high temperature alloy, aluminum 5A06, aluminum 7075, the hardness or tensile strength value is high, these special metal spinning material will break in the cold spinning. Second, when the blank thickness is over 5mm, exterior materials (that is touch the metal roller ) will flow quicker than interior materials, heating can keep the exterior materials and interior material flow almost same, the fatigue mark of interior surface will reduce. Third, the thicker and harder metal spinning will need stronger spinning force without heating, hot metal spinning can reduce the wear of lead screw and spindle.

3) Sheet spinning and tube spinning >>

Sheet Spinning is suitable to make the spun product that diameter value is bigger than height (such as diameter is 500mm, height is 100mm, the diameter > 1-3 times * height ), but tube spinning is suitable to make the diameter value is little than height value, (such as diameter is 200mm, height is 400mm, the height >1-3 times * height).

When the height value is too big, the ductility is not enough that can make blank sheet will break in metal spinning, so the advantage of tube spinning can avoid this risk, tube spinning forming can use necking forming to make the shape.

5. Metal spun forming technology

Conventional : conventional are used cylinder metal spinning usually, the height value of cylinder is big ,the metal spinning is hard.

Shearing : the cone angle >20º, it can be spun by shearing. thickness after spinning = blank thickness *sin α.

Expanding / Necking : expanding will reduce the blank thickness, necking will increase the blank thickness.

Rolling : when the diameter >350mm, rolling is hard to make in the metal spinning mold, you need to design a interior hydraulic fixture to support the work piece to roll.

Flanging : the blank rolling cylinder need to weld well, otherwise the welding position is easy to break after flanging.

Metal flowing : it is applied in three roller metal flowing machine to form the missile shell and automobile wheel spinning.

6. Metal spinning path >>

CNC path of roller : CNC path is the most important technology in metal spinning process, you need to know the spun prosperity of different materials, what shape of the metal spun product decides to draw the right CNC path in the CAD software, an experienced metal spinner needs 5 years and make metal spinning products over 100 kinds, they will can draw the correct CNC path, of course, they also needs to try according to the actual situation. There are basic metal spinning solutions when you have the following problem in metal spinning process.

7. Metal spinning process problem >>

1) Conventional spinning

● Crinkle in the edge of Max diameter of work piece

Crinkle in the edge as the edge is too soft, thin sheet is obvious when the thickness is less than 1mm, you need to reduce the radius of roller or reduce the radius of go path, or use the backing roller improve the strength of edge.

● Break in the area close to the mold

Break position as the work piece is too thin, you can find the radius of the edge is two litter, the litter diameter position make the roller pull the material too much, then the work piece will thin, you can increase the radius of roller or the radius of go path. Other ways is use back path to reduce material thinning and reduce the gap make work piece hold the mold tight.

2) Shear spinning

Shearing spinning need to control the right spindle speed, gap and feed back.

● Interior have not touched the mod : you can check the interior of metal spinning products, if it is not smooth or bright, the interior is not touched the mold, so you need to reduce the gap.

● Work pieces material backflow : the gap is too little, so the material will backflow, you can find the exterior will have shaking line that is not uniform compare to the normal spinning line.

There is best way to check the gap is right : the gap is little, the flange of work piece will move forward, the gap is big, the flange of work piece will move backward. If the gap is normal, the flange is straight and flat.

3) Tube /necking / expanding spinning >>

When you make tube /necking / expanding spinning, the metal spinning path is not so important, the fixturing is most important. You must need to design and make a fixturing to clamp the position near by your spinning roller first touch point. If the support and clamping force is enough, it will be spun very smoothly, if the support position have gap with the work piece, the clamping force is not enough, it is easy to crinkle and break in the final.

4) Thickness control

There are three ways to control the final thickness after spinning. At first, to increase the blank thickness. Second, you can adjust the cnc metal spinning path, increase the radius of go path and use the back path. Third, you can use the big radius of roller to spin.

5) Accuracy control >>

There are four ways to control the metal spinning accuracy. At first, you need to control the runout accuracy of spun roller. Second, you need to control the runout accuracy of mold. Third, you need to use the right meta spinning path to make the work piece hold mold tightly. Fourth, you need to control the work temperature to avoid the mold and roller expansion and contraction.

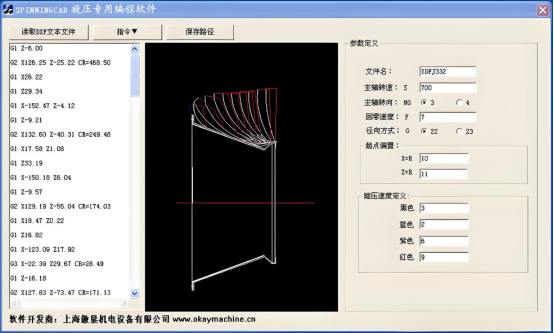

8. CNC metal spinning program

When you finish the CNC path drawing, you can make a CNC metal spinning program by the CNC path. Now many CNC metal spinning machine company can offer you a automatic CNC program soft instead of manual writing, different CNC metal spinning have different CNC system, so the CNC program is different, the most widely used in they world is Siemens system. If you know CNC programming, you can learn metal spinning programming quickly, the basic programming code is same, the following is the an simple CNC metal spinning program.

Two software : CAD to drawing the CNC metal spinning path, MAXCAN to find out the coordinate value.

CNC metal spinning program code

M3 /M4- spindle clockwise / counterclockwise rotation

S800 - spindle rotation speed 800r/min

G1 - straight move

G2 - clockwise Round move

X-0.7 Z9.5 - the absolute value of coordinates

G3/G4 - clockwise / counterclockwise round move

F 7000 - feed speed 7000mm/min

9. Automatic CNC programming software

It reduce the workload of metal spinner and improve the programming efficiency. Many CNC metal spinning machine /lathe manufacturing company will offer the CNC programming software to you after buying the machine, DENN, Lefield, MJC, Prosper, OKay have developed their own CNC programming software.

10. CNC metal spinning paramter >>

Spindle speed : Thick sheet, harder metal and big diameter needs lower spindle speed, soft sheet, thin sheet and little diameter needs higher spindle speed.

Feed speed : Increasing the feed speed can improve the production efficiency. feed speed is quicker in metal spinning forming, the thinning is less and the exterior surface is worse, the feed speed is slower, the thinning is more, the exterior surface is smoother.

Clamping hydraulic pressure : You had better to adjust the clamping force can make blank sheet does not rotate relative to the mold, more clamping force can make the spindle and clamping bearings wear quickly.

Recommended

- -Top twelve metal forming fabrication methods

2025-11-22 - -What is CNC metal spinning machine tool

2024-08-15 - -Aerospace components-Precision manufacturing of CNC spinning

2025-01-29 - -Metal spun products - what product spin forming can do

2025-01-24 - -How to design a CNC metal spinning mold | mandrel

2024-04-12 - -Metal spinning materials

2024-04-14 - -Metal spinning development and prospect

2024-10-31 - -How to choose a CNC metal spinning machine

2024-04-18 - -Metal spinning process and technology

2024-11-30 - -How to control the accuracy of CNC metal spinning

2024-07-27