How to choose a CNC metal spinning machine

Many customers consider to buy a CNC metal spinning machine tool, except to consider the price, performance and dimension of the equipment, you should pay attention to several important knowledge and product requirements like the following introduction in details.

● Heavy duty and and light duty machine

Heavy duty CNC metal spinning can output stronger spinning force to form the thicker and harder metal, when the thickness of metal is thick ( aluminum >3mm, steel >2mm,stainless steel >1.5mm ), you should choose the a heavy duty CNC metal spinning machine, the motor power is higher, the lead screw and bearings are bigger to bear strong spinning form force.

Light duty CNC metal spinning can output less spinning force with a higher spindle speed ( spindle speed can achieve 1500 rpm). The feed speed is faster and production efficiency is higher, it save production cost when it is used to spin the thin metal. If you use the light duty CNC metal spinning machine to spin the thick metal, the machine will stop working when the motor overload or the bearing and lead screw will wear quickly.

● Single roller and double roller machine

Double roller CNC metal spinning machine can be beared blance spun force and work fastly, the thickness of double roller after spinning is thinner than single roller, but the thickness of double roller is more uniform, the accuracy of double roller is higer. So if your spun products needs accuracy, you had better choosse the double roller.

Single roller CNC metal spinning machine is cheaper than double roller, if you make some spun products like tableware, cookware that don't need accuracy, you can choose a single roller.

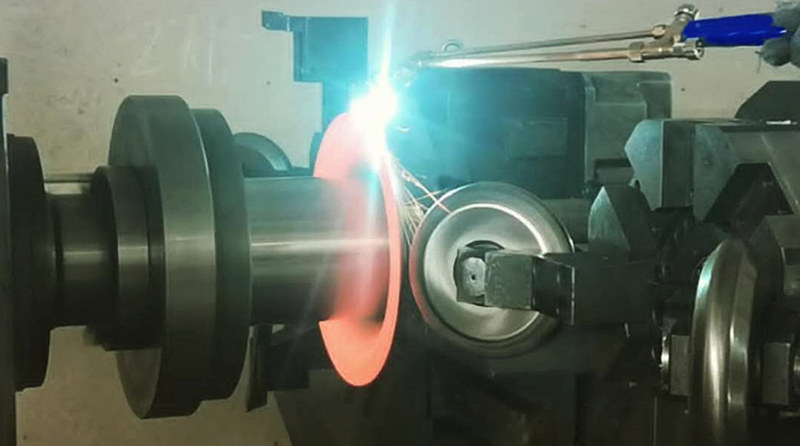

● Heating and cold metal spinning machine

If the thickness of aluminum > 8mm, steel >6mm, stainless steel >5mm. heavy duty CNC metal spinning machine will bear strong spun force to form the metal, it will reduce the spun force when we spin thick metal with heating, so heating CNC metal spinning machine needs to assemble the heating equipment inside. Heating machine includes propane heating ,high-frequency heating.

Some special metal needs heating spun like hardox, inconel, SUS630, TC4, these metal has higher hardness and tensile strength, the ductility is worse to spin, so these metal must be spin with heating, otherwise it will break in cold spinning.

If the metal is thin and soft, you can choose the cold spinning machines.

● Sheet spining and tube spinning machine

The structure of sheet metal spinning machine and tube metal spinning machine is different, sheet metal spinning machine needs tailstock to press the sheet on the mold, then the friction force between mold and tailstock can take sheet follow the spindle, tube metal spinning machine don't need tailstock, the blank tube be hold by the hydraulic fixture and it spin follow the spindle.

If you need to make tube and sheet metal spinning in a machine, you need to keep the tailstock ,when you make sheet spinning, you needs tailstock to press sheet, when you need to make tube spinning, you can assemble the hydraulic fixture.

If you need to know more knowledge of CNC metal spinning machine, you can read this article what is CNC metal spinning machine tool >>

Recommended

- -Estimation of the blank diameter or thickness of spin forming

2025-04-26 - -A complete guide of CNC metal spinning machine

2025-04-06 - -Aerospace components-Precision manufacturing of CNC spinning

2025-01-29 - -How to improve the surface quality of CNC spinning

2025-03-06 - -Spin forming expert ▏Eight important metal spinning forming knowledge

2025-03-05 - -What is CNC metal spinning machine tool

2024-08-15 - -Metal spinning materials

2024-04-14 - -How to design a CNC metal spinning mold | mandrel

2024-04-12 - -Metal spun products - what product spin forming can do

2025-01-24 - -How to choose a CNC metal spinning machine

2024-04-18