What is CNC metal spinning machine tool

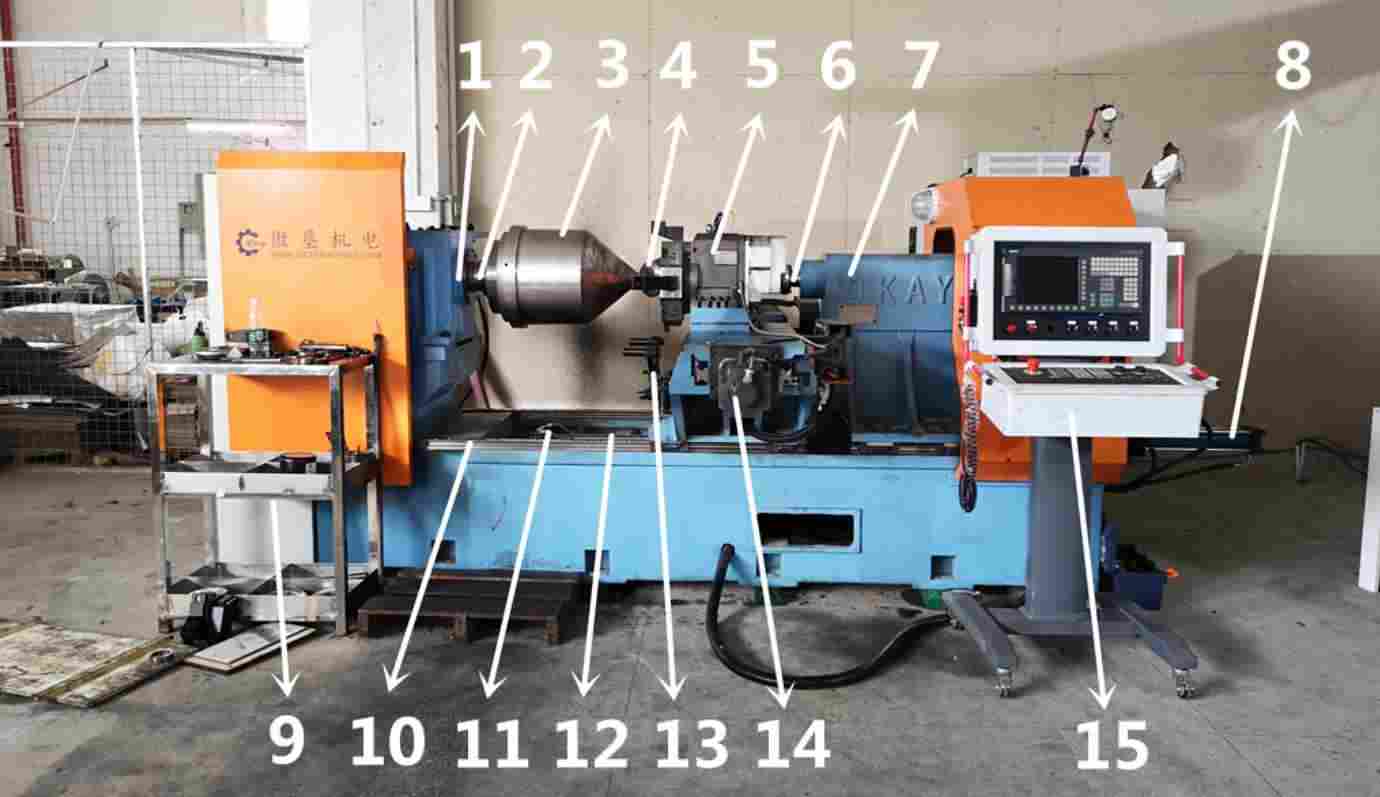

CNC metal spinning machine tool

CNC metal spinning machine is an equipment to make metal form different shape according to CNC path, The structure is similar with CNC turning lathe, but CNC metal spinning machine have quicker feed speed and stronger torque and process force, CNC turning lathe have higher spindle rotational speed. CNC metal spinning machine tool not only can form the blank sheet by metal spinning roller, but also can use the turning tool to cut the edge. The main components includes lathe bed, servo motor, lead screw, guide rail, headstock, spindle, tailstock, hydraulic cylinder, tool mounting, the hydraulic pressure station. CNC system control all the components work and move by CNC program.

Mechanisms and machine theory

There is two main mechanical action in the CNC spinning machine. At first, spindle and clamp take the sheet to spin together. Second, roller press and pull the blank sheet according to the CNC program.

Components and functions

1. Headstock : It is used to assemble spindle inside.

2. Spindle :it is used to assemble and lock mold.

3. Metal spinning mold (Mandrel) :it provide support and clamp force to the blank sheet, roller press the blank sheet on mold and make the blank sheet surface smooth.

4. Metal spinning roller(wheel) : it press and pull blank to form according to CNC path.

5. Tool mounting : it is used to assemble spinning roller and turning tool.

6. Hydraulic cylinder 1 : it offer hydraulic force to press bank sheet to the bottom of mold.

7. Tailstock : it is used to assemble the hydraulic cylinder 1.

8. Hydraulic cylinder 2 : it is used to reduce the distance between tailstock and headstock.

9. Spindle serve motor : it output the torque to spindle and take spindle to spin.

10. Guide rail : it keep X-axis or Y-axis to move straightly ,straightness accuracy is +-0.02mm.

11. Bearing housing : it is used to assemble bearings, so the lead srew can spin follow motor.

12. Lead srew : it make motor rotation translates into move straightly.

13. Loading rack :it connect with a air cylinder . it is used to load the blank sheet and position it.

14. X-axis motor : it outputs the torque to make X-axis move.

15. Operation panel : adjust and control the parameter and machine operation.

Name and specification

Such as 800 double roller heavy duty CNC metal spining machines

800 means the maximum blank sheet diameter.

Double roller means it can keep double roller to spin at the same time.

Heavy duty means stronger spinning force to spin thick wall sheet .(stainless steel thickness is over 3mm)

Process step

Step 1 : Air cylinder raises loading rack, labor put the blank sheet on the loading rack.

Step 2 : clamp (hydraulic cylinder 1 output the hydraulic force )press the blank sheet on the bottom of mold.

Step 3 : spindle motor output the torque and take spindle, mold, blank sheet and clamp(there is bearing inside the clamp) to spin together.

Step 4 : roller move according to the CNC program ( CNC path ).

Step 5 : Clamp back, remove the metal spinning products.

The key parameter of CNC metal spinning machine

1.Servo motor power : it decides the output spinning force can process thickness.

2.Feed speed : feed speed decides the metal spinning process time and efficiency.

3.Blank sheet diameter : it decides Max diameter can be spun.

4.The distance between spindle and hydraulic cylinder 1 : it decides the Max height can be spun

The price of CNC metal spinning machine

Many people want to buy a CNC metal spinning machine tool, there are companies to supply many CNC metal spinning machine ,you can ask the quotation from them to get the price and technical parameter. But you don't know how to judge whether the machine is expensive or the machine fits your products. The main cost of CNC metal spinning machines is related to casting lathe bed size and weight, servo motor power, guide rail and lead screw specification, system brand (siemens is the good choice), these are main and expensive part of CNC metal spinning machine, the specification and valve is bigger, the cost is more expensive, you can access the the price from these parameter.

Which company is good to buy a CNC metal spinning machine>

There are several famous CNC metal spinning machine manufacturing companies for your choices.

1. Leified is a Germany company

2. MJC is a American company

3. DENN is a Spainish company

4. Prosper is a Chinese company

5. OKay is a Chinese company

6. Denlis is a Chinese company

Which accessories need to be made

1. Mold : Every metal spinning products needs to make a new mold.

2. Clamp: Clamp Max diameter is same with the diameter of mold bottom.

3. Roller : forming different shape needs different radius of roller (radius is 1-14mm).

4. Loading rack : it need to adjust the right height only.

5. Backing air pressure roller : it is used to form flange or support the edge of thin sheet spinning. (thickness is less than 1mm)

Inclusion : You just need to make mold, roller, clamp when you spin a new metal spinning product.The loading rack and the backing air pressure roller don't need to make, you need to check whether these two accessories in the CNC metal spinning when you buy.

What decides the performance of the CNC metal spinning machine

1. Accuracy :Repeated positioning accuracy

All the accessories needs qualified precision and right machine tool assembly technique, it has better to control repeated positional accuracy within 0.02mm, good repeated positioning accuracy of CNC metal spinning lathe can process better accuracy of metal spinning product.

2. Long -time accuracy : Casting lathe bed heating treatment

Casting lathe bed must remove the internal stress by heating treatment. If the casting lathe bed haven't heating treatment and natural stress relief, the lathe bed will be deformed as the role of internal stress and lose the mechanical precision in the long-term production.

3.Spinning force tolerance : Rigidity and strength of machine bed

The lead srew, guide rail and wall thickness of casting machine bed decides the rigidity and strength, better rigidity and strength of CNC metal spinning lathe operate and work more stably.

5. Spinning force output : Servo motor power

Servo motor power valve is big, it can output stronger torque and spin thicker wall.

6. Feed speed : helical pitch of lead screw ,the motor of X-axis and Z-axis

Big specification of lead screw and guide rail can bear stronger spinning force, little specification of lead screw and guide rail can move fast.

Maintenance of machine

1. Labricating oil : guide rail, lead screw, hydraulic cylinder needs to oil to reduce wear.

2. Daily cleaning : to clean the greasy dirt and icon scrap.

3. Mold weight: it need to reduce the mold weight to reduce the spindle abrasion.

4. Clamp force : to use the Min hydraulic pressure as possible if the clamp can hold the blank sheet tightly, to reduce the abrasion bearing of spindle and cylinder.

How to design a high performance machine

Many people are interested in how to design a CNC metal spinning machine, Before you design a CNC metal spinning lathe ,you need to know what is the technical requirement of metal spinning products in different industry, you will have a good design plan after you find the marketing requirements. There is three main marketing direction you need to consider in total according to the spinning force of CNC metal spinning machines.

1.Consumer good

Specification : blank diameter - 300mm distance between spindle and clamp - 500mm

Max spindler speed : 1800-3000r/min

Max feed speed : 6000-12000mm/min

Thickness : stainless steel ﹤1mm steel ﹤1.2mm aluminum ﹤1.8mm

Consumer good are the light weigh, thin wall and smooth surface, the order quantity is more and unit price is cheap, to improve the production efficiency of CNC metal spinning is the key goal. In order to improve the production speed, Maxis spindle rotate speed is 2000-3000 r/min, Max feed speed is 8000-15000mm/min, guide rail is about 20mm, lead srew is about 25mm, high speed bearing is a good choice ,it can make the blank sheet form faster.

You also can use a air cylinder instead of hydraulic cylinder in tailstock, air cylinder clamp force is less than hydraulic ,but air cylinder is faster to move.

Special device : air pressure backing roller is used to support and improve the edge of thin sheet metal spinning. It is benifit for metal forming.

Application : tableware, lamp shadow, home decoration, bottle, cup, vase.

2.Precision mechanic components

Thickness : stainless steel ﹤3mm steel﹤4mm aluminum﹤6mm

Specification : blank diameter - 800mm distance between spindle and clamp - 1200mm

Max spindle speed : 1000-1500r/min

Max feed speed : 4000-6000mm/min

Precision mechanic components are used in the equipment or machine, the thickness is bigger than consume good, the accuracy is required to assemble or hardness and tensile strength is required in working environment. As we know, the valve of the hardness and tensile strength is bigger, the spinning spring back is big and it needs more spinning force to form. So we need to choose bigger specification of guide rail and lead screw, guide rail is about 40mm, lead screw is about 50mm, servo motor power is about 20-30KW, X-axis and Z-axis is about 10-12KW. If the power is not enough, The torque and spinning force is not enough, you can choose deceleration and torque increase theory to improve the torque. On the other hand, you need to control the positional precision with 0.02mm, Casting lathe bed is convenient to make CNC milling and assemble the all the components.

The hydraulic cylinder must be used in precision CNC metal spinning machine, except the output force is stronger than air pressure, the output pressure and force is more stable.

Application : combustion chamber, nozzle, turbojet, medical equipment, venturi, reflector, funnel ,automobile air spring.

3. Heavy duty metal spinning parts

Thickness : stainless steel ﹤6mm steel﹤8mm aluminum﹤12mm

Specification : blank diameter - 1500mm distance between spindle and clamp - 1800mm.

Max spindle speed : 600-1000r/min

Max feed speed : 2000-3000mm/min

Heavy duty CNC metal spinning machine are used the thick wall and large diameter metal spun products, the diameter is bigger or the thickness is thicker, it needs stronger torque and spinning force to process the blank sheet. There are two ways to improve the spinning force. At first, to use bigger spindle, X-axis and Z-axis servo motor power, heavy duty spindle motor is more than 40KW. Second, You can use belt pulley structure to reduce the rotational speed of motor output and improve the torque and spinning force. this way will reduce the spindle speed or feed speed.

Special device : two hydraulic cylinder are used in the tailstock, one is used to clamp the blank sheet. Another is used to reduce the distance between mold and clamp ,it can improve the reduce the runout of hydraulic cylinder 1.

Application : fan ,equipment part, aerospace, reflector.

The performance of different CNC metal spinning equipment

There are too many types of CNC metal spinning machines in the marketing, we introduce the basic structure and performance according to different machines from different company. We can distinguish these machine by the spinning force, the structure of casting lathe bed, metal spinning roller quantity.

Spinning force classification

1. Light duty CNC metal spinning machine

Advantage : Light duty metal spinning machine is suit to make the thin metal sheet, it is mainly applied in lampshade ,tableware ,home decoration crafs, these metal spinning products needs good surface and thin thickness. Light duty metal spinning machine have higher rotating speed and feed speed than heavy duty CNC metal spinning machine, so the exterior surface of metal spinning product will be more smooth and the production efficiency will be quicker.

The disadvantage : light duty metal spinning can't spin the thick metal sheet, if you spin the thick metal sheet, the lathe bed will break as the strength is not enough, guide screw will wear quicker as machine bearing more spinning force, motor cause serious electrical burn as under powder.

Light duty single roller parameter and price

Blank sheet diameter : 600mm

Spindle motor power : 8KW

Thick : stainless steel thickness <1.2mm, aluminum thickness <2mm ,steel<1.5mm

RPM( revolutions per minute ) : 3000 r/min

Max feed speed : 10000mm/min

Equipment price : it is about 8000 dollars

2. Heavy duty CNC metal spinning machine

Advantage : Heavy duty metal spinning can process thick metal sheet with stronger spinning force, it can process thin wall sheet as well. The specification of motor and guide screw is bigger than light duty metal spinning machine.

Disadvantage : but RPM and feed speed is slower, the production efficiency is slow.

Why heavy duty machine is expensive : the servo motor power is bigger and more expensive, the specification of lead srew ,guide rail and bearing is bigger, the lathe bed thickness is thicker and weight is heavier.

Heavy duty CNC metal spinning machine parameter and price

Blank sheet diameter : 600mm

Spindle motor power : 20KW

Spinning thickness : stainless steel thickness -3mm,aluminum thickness -6mm,steel -4mm

Spindle RPM : 1800r/min

Max feed speed : about 6000mm/min

Equipment price : > 40000 dollars

Metal spinning roller quantity classification

3. Single roller CNC metal spinning machine

Advantage : it have only one roller and motor on the X-axis .single roller spinning have thick wall after finishing metal spinning, but the metal spring back is bigger than more rollers spinning.

The disadvantage : blank sheet only bear one roller press and pull, the spinning force is not balance and strong compare to double roller.

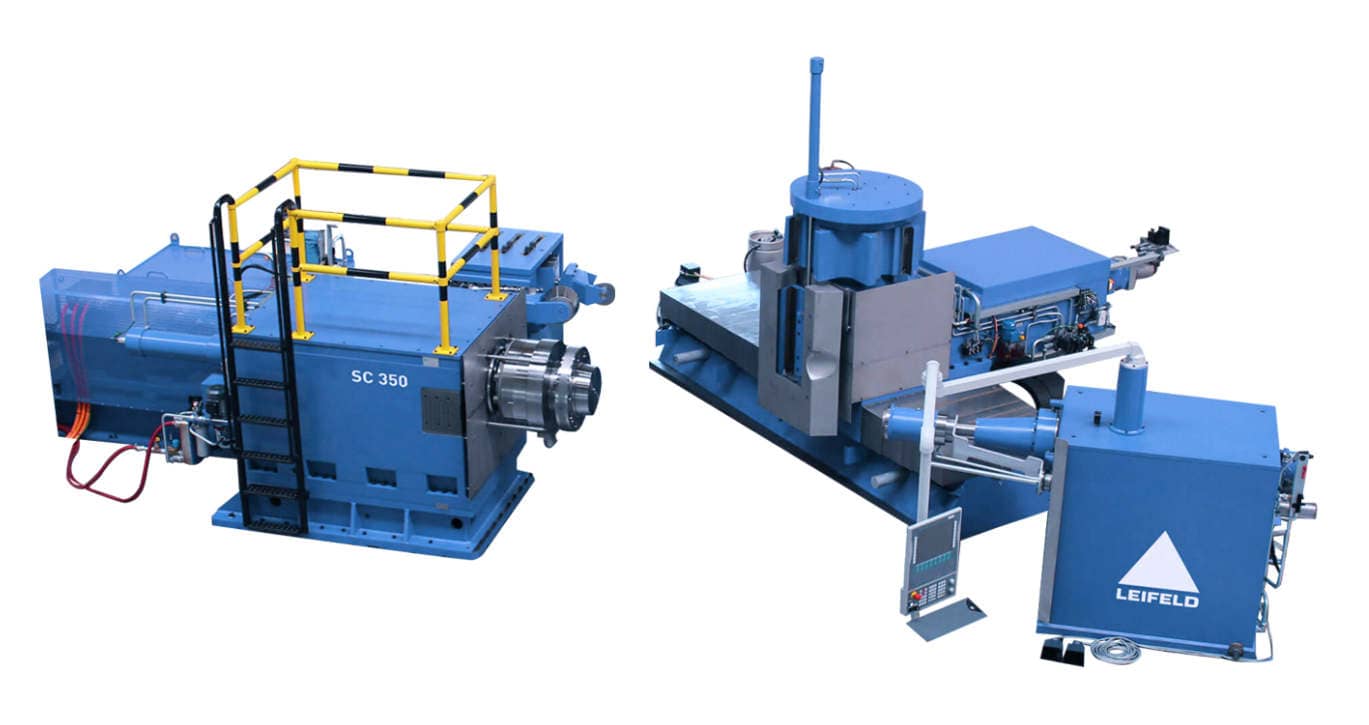

Equipment image : Leifeld from German

Specification : NIHON SPINDLE T500 -NC-T4

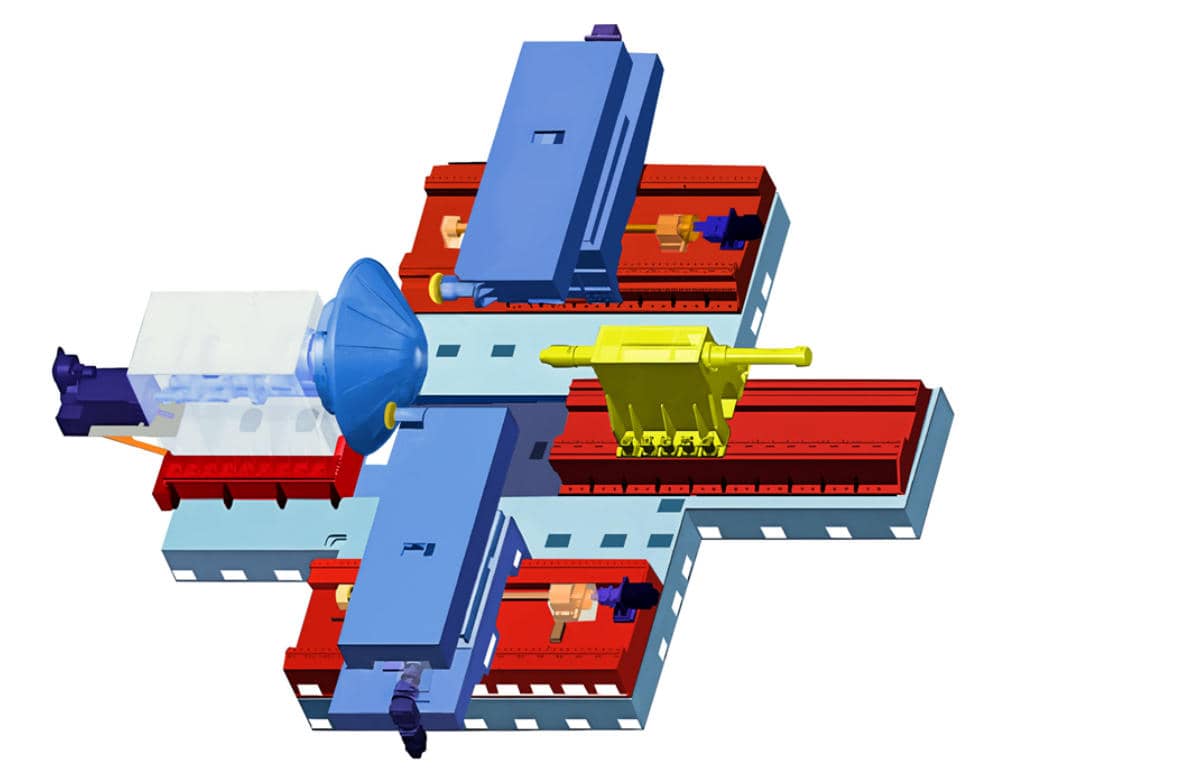

4. Double roller CNC metal spinning machine

Advantage : it have two roller and motor on the X-axis, but the metal spinning back is less and spinning force is stronger.

The disadvantage of double roller : the price of double roller is more expensive than single roller when the specification of machine is same.

Equipment image : Dinnovation from China.

5. Three roller flow forming machine

Three roller shear flow is applied in military to make sheer spinning, shear spinning can make grain refinement and improve the tensile strength, hydrogen cylinder, tank cylinder and military shell needs three roller to make the cylinder and improve the strength at first process, then use the tube spinning to make necking.

Application : Military and high pressure tank

Equipment imge : MJC from America.

Lathe bed structure classification

8. Vertical CNC metal spinning machine

Advantage : the spindle of vertical CNC metal spinning machine is vertical. First, it is easy to loading and unload in the production. Second, the blank metal as the direction of gravity of metal is same of the spindle axis, the blank can put on the bottom of mold flatly and it does not slip easily. Third, the spindle and Z-axis are less effected by gravity. When the weight of mold is heavy, vertical machine is better choice. Fourth, the covering area is less, it is suitable to make the bigger diameter and less height metal spinning product.

Disadvantage: the height of vertical CNC metal spinning is higher, if the height of metal spinning product is over 500mm, it is hard to remove the products from vertical metal spinning machine.

Application : it is applied in tableware (pan ) and automobile wheel (hub ) mostly.

Equipment imge : DENN from Spain.

9. Slant bed CNC metal spinning machine

Advantage: First, it is easy to load and unload in the production. Second, it have strong rigidity as taper self-locking. Third, it is easy to clean the metal filings after production. Fourth, the covering area of slant bed is small, but it's heights is higher.

Disadvantage: it is hard to process the lathe bed by CNC milling machine, it is hard to assemble the lead srew and guide rail on the slant bed.

Application : Slant bed CNC metal spinning machine applied in single roller and small size metal spinning machine ( process diameter is less than 800mm), when the size of CNC metal spinning machine is big (diameter is over 800mm), it is not suitable to make a slant bed, all the components will bear the big weight (gravity ).

Equipment image : Leifeld from German.

10. Flat bed CNC metal spinning machine

Advantage : Flat bed machine is easy to assemble the machine tools and process the casting lathe bed.

Disadvantage : it is hard to load and unload the products, too little metal spinning is not suit to design flat bed.

Application : CNC metal spinning process diameter is less than 800mm, you can see slant bed and flat bed CNC metal spinning machine, when the diameter is over 800mm, flat bed is good choice for big size metal spun product. At first, flat bed is convenient to assemble the components. Second, the slant machine will bear the gravity of the fittings, it will reduce the work life of lead srew.

Disadvantage of flat bed : first, it is easy to assemble the components as it can put on the floor. Second, it can save the lathe bed cost.

Equipment image : Leifeld from German

Inclusion : CNC metal spinning structure of lathe bed design

1. vertical lathe bed (height <200mm,diameter <200mm)

Vertical CNC metal spinning machine is convenient to load and unload the little metal Spinning products. You had better to keep the spindle height is about 1.3m, it is comfortable to put the metal sheet.

2. Slant lathe bed ( diameter is about 200mm,height >250mm)

Slant CNC metal spinning machine is convenient to load and unload the long cylinder of metal spinning products. It is hard to assemble machine tools and to process the lathe bed that is made by CNC milling, the spindle height is about 1m.

3. Flat lathe bed ( diameter >8000mm,height >500mm)

Large and heavy duty CNC metal spinning machine is made by Flat structure, it is convenient to assemble the machine tools, debugging work and loading material is more safe.

Special metal forming equipment

11. Automobile hub (wheel )

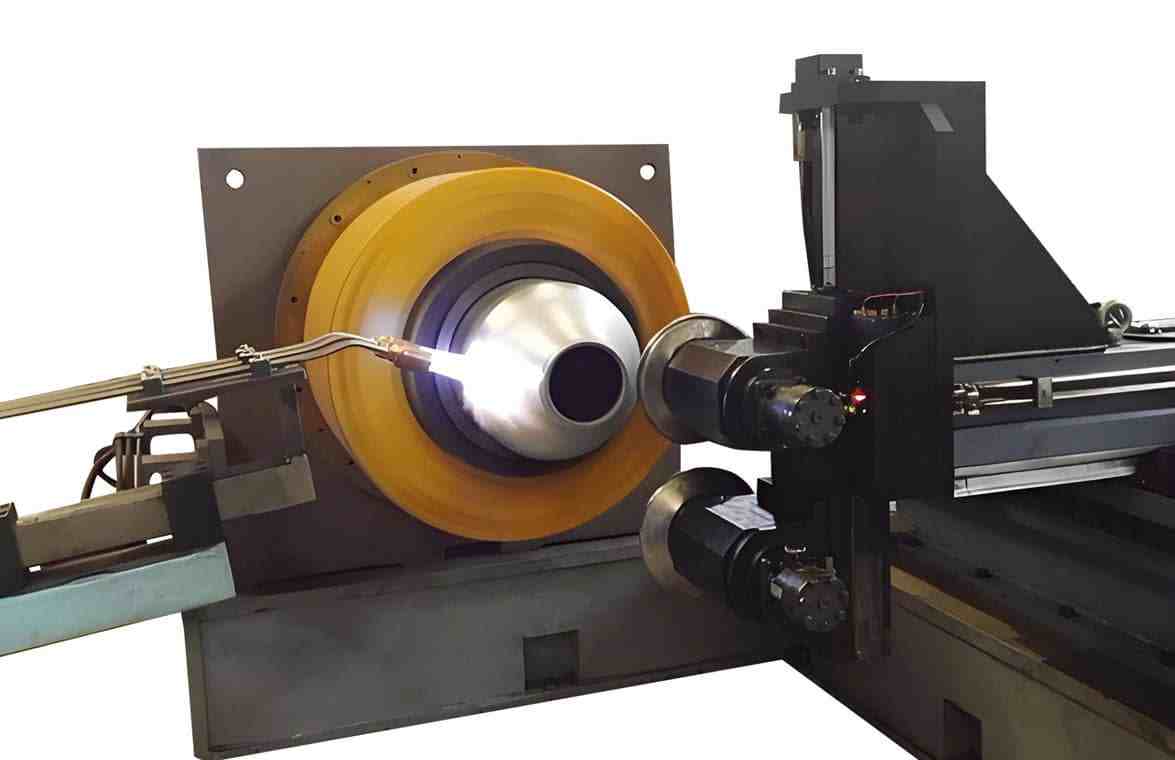

The hub (wheel ) forming machines are generally vertical lathe bed. Hub metal forming will produce heating and the weight is heavy, it hard to load and unload by hand, vertical machine is convenient to achieve automatic production, the spinning force is not outputted by motor and screw, it is outputted by hydraulic pressure directly, the blank casting wheel will improve the tensile strength after metal spinning.

Application : automobile hub (wheel )

Equipment image : Dienlis from China

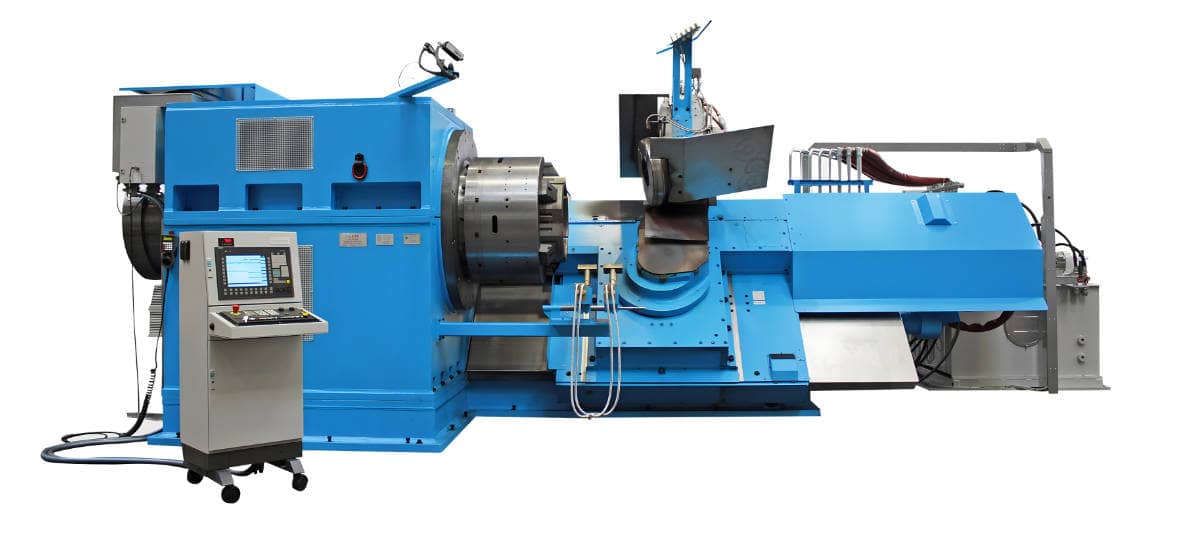

12. Oxygen and hydrogen tank tube

Oxygen tank hot metal spinning machine have custom spinning fixture and heating equipment, but it haven’t tailstock ,the centre holes of the spindle (less than 60mm) in sheet spinning machine is used to through gas to remove the metal spinning product. If the holes is too big, the spindle bearing need bigger specification, bigger bearing wear speed is quick and rotary speed is slow. The spindle of oxygen tank CNC metal spinning machine is bigger with a bigger centre hole. The heating device will make the blank tube rise the temperature and soft, then rolle can form it with heating.

Application : oxygen tank ,hydrogen cylinder

Equipment image : OKay from China

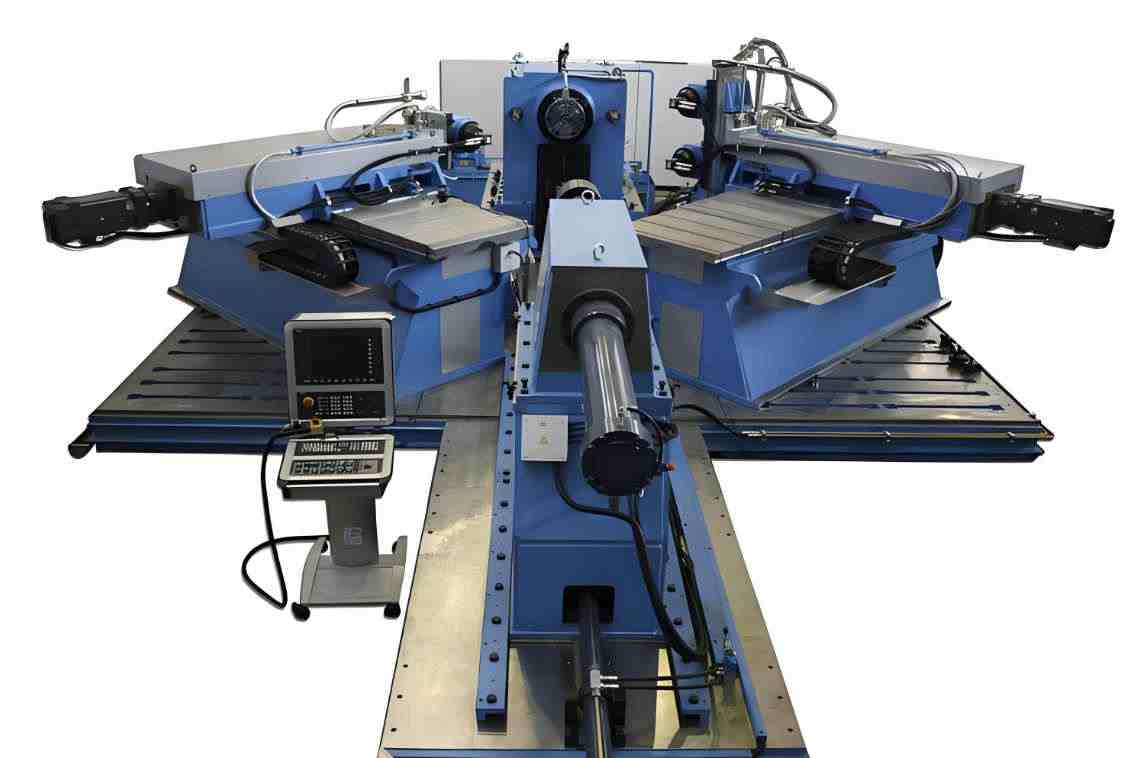

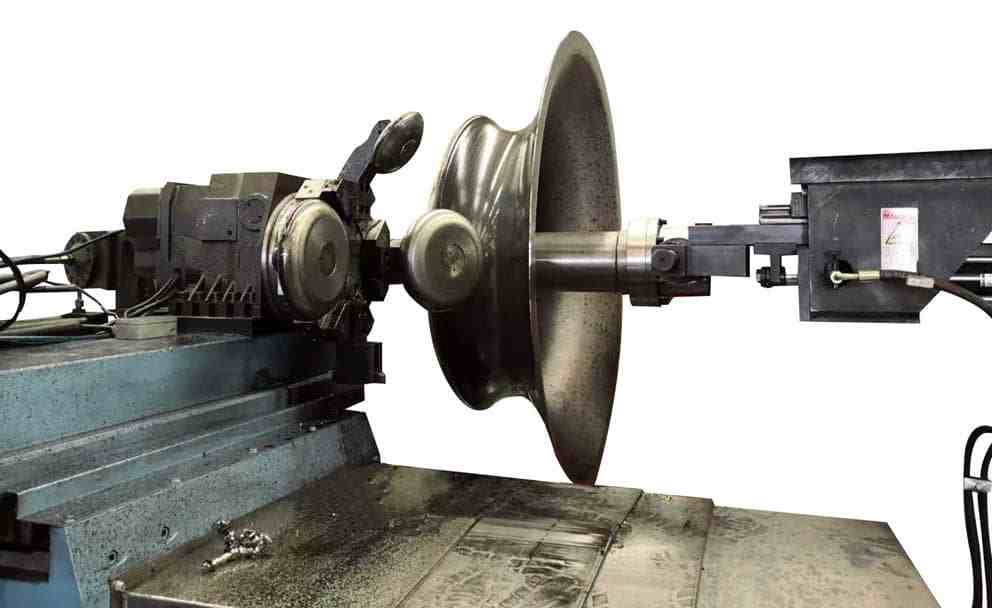

13. Fan no-mold metal spinning forming

Fan components are large diameter, the diameter >500mm, it is expensive to make a big metal spinning mold. In order to save the mold cost, no-mold metal spinning is used in fan metal spinning .there is no-mold inside, clamp press the blank sheet in a little mandrel and take blank sheet to spin, then metal spinning roller make the blank sheet form. At last, the backing roller will push the flange edge and make the flange flat.

Application : air inlet shell, air out let shell ,fan.

Equipment image : OKay from China

14. Flanging machine

Flanging machine is use to make axial fan housing, the blank cylinder is made by rolling and welding, the put the blank cylinder into the fixture of flanging machine. It will take 4 minutes to form a flange, production efficiency is higher compare to traditional welding two flanges, it save materials cost and mold cost at the same time .all the holes on the flange can be finished in the flanging machine, you don't need to make holes in other machine any more.

Application : fan ,axial fan

Equipment image : Prosper from China

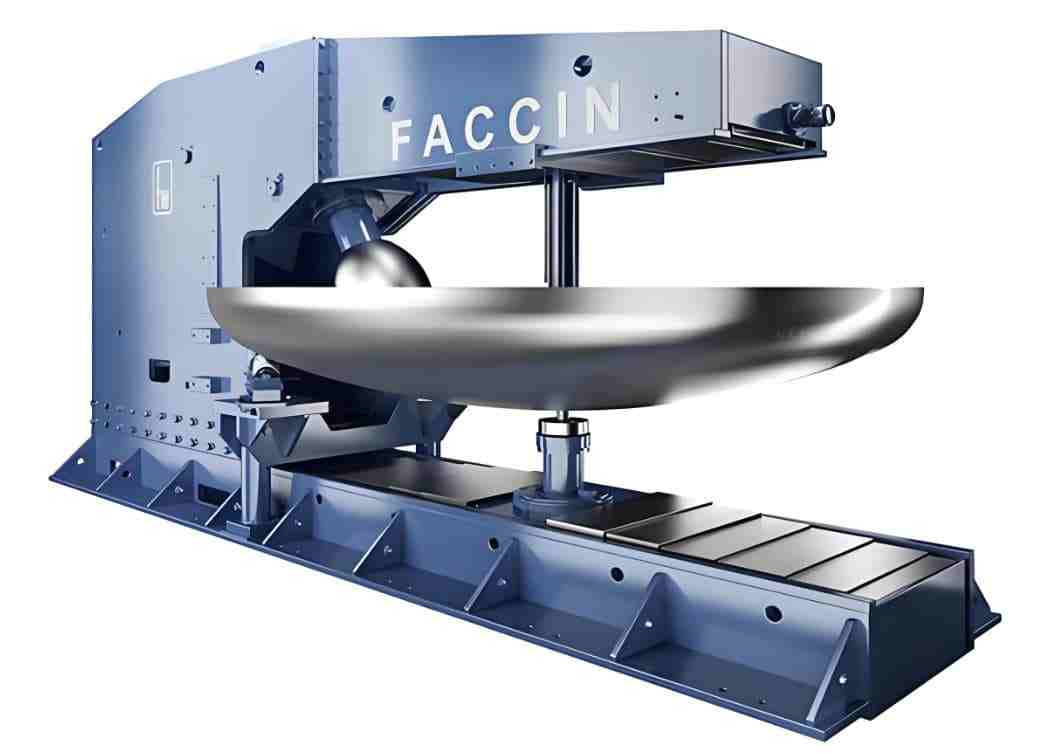

15. Head metal forming

Head metal forming machine are applied in head industry, head is a part of pressure container, you also can make it by shearing metal spinning or deep drawing, but the mold cost of big diameter of head is expensive, head metal forming machine can make the head without mold.

Application : big head (diameter >500mm)

Equipment image : FACCIN from Italy

Recommended

- -Spin forming principle-CNC metal spinning technology

2026-02-22 - -What is CNC metal spinning machine tool

2024-08-15 - -Aerospace components-Precision manufacturing of CNC spinning

2025-01-29 - -Metal spun products - what product spin forming can do

2025-01-24 - -How to design a CNC metal spinning mold | mandrel

2024-04-12 - -Metal spinning materials

2024-04-14 - -Metal spinning development and prospect

2024-10-31 - -How to choose a CNC metal spinning machine

2024-04-18 - -Metal spinning process and technology

2024-11-30 - -How to control the accuracy of CNC metal spinning

2024-07-27