Estimation of the blank diameter or thickness of spin forming

Many metal spinner are confused how to calculate the blank diameter of metal spinning. In spinning forming principle, blank thickness will change in spining, but the weight of blank material and final work pieces are same. If we want to calculate the blank diameter, we need to calculate the weight of blank materials and metal spun product .

1. Metal spun product weight

Final work piece weight(metal spun product) = blank weight - trimming weigh

You have three way to get the final work pieces weight, at first, you can weight the metal spun sample of your custom. Second, you can use UG or ProE software to open the 3D model to measure the quality.

Trimming weigh is about = final work pieces * 0.01

Blank diameter = √(blank weight / π/ thickness)

As the spin forming can make the thickness thinning, so we need to know what original blank thickness used.

2. Blank materials thickness changes after spin forming

The thickness of blank materials will change after spinning, such as conventional spinning, expanding and shearing spinning will reduce the thickness of blank materials, the necking will increase the thickness of blank materials. Now we distinguish the thinning rate according to different spin forming methods.

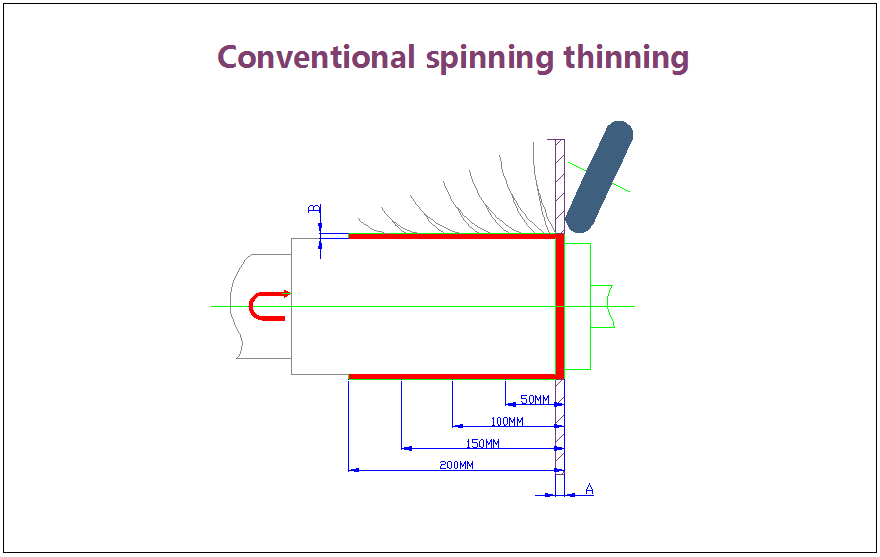

① Conventional spinning and cylinder thinning

Cylinder is typical conventional spinning , you can see the image above, actual the cylinder height is higher, the thinning rate is bigger.

●Stainless steel thinning rate

Height is 50mm,spinning thickness B = A* 0.75

Height is 100mm,spinning thickness B = A*0.6

Height is 150mm, spinning thickness B = A*0.5

Height is 200mm, spinning thickness B = A*0.4

● If you spin steel and aluminum, the thinning rate is little than stainless steel .

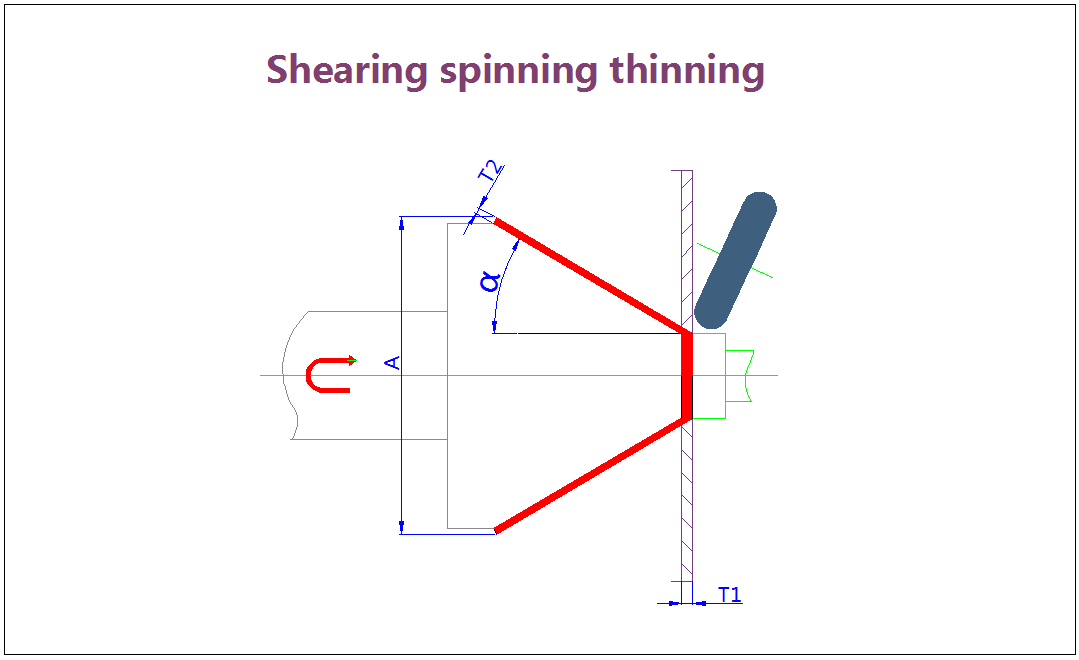

② Shearing spinning thinning

Shearing and spinning make blank sheet shear deformation, the angle α valve is bigger, the thinning rate is little.

(Spinning thickness ) T2 = (blank thickness) T1*Sinα

Blank diameter = (Max diameter )A + B

B=10-50mm( diameter is bigger, angle αis bigger, the B valve is bigger, such as diameter is 800mm, angle αis 45º, B valve is 50mm, the diameter is 200mm angle is 70º,B valve is 10mm.

When the angle α>20º,it can be formed by shearing spinning.

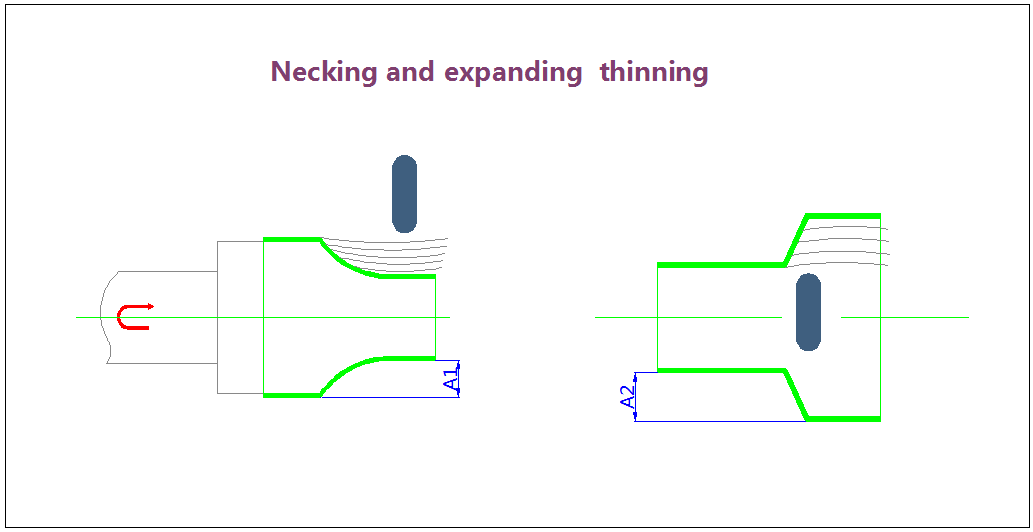

③ Necking and expanding thinning

Necking thickening and expanding thinning decides the A1 value,the A1 value is bigger,the necking thickening is more, the expanding thinning is more.

A1 or A2 = Max diameter - Min diameter

Necking thickening and expanding thinning is about 10%-60%. Orange peel is prone to form inside the necking interior materials with the thickening, you can use heating to improve the flowing speed of interior materials.

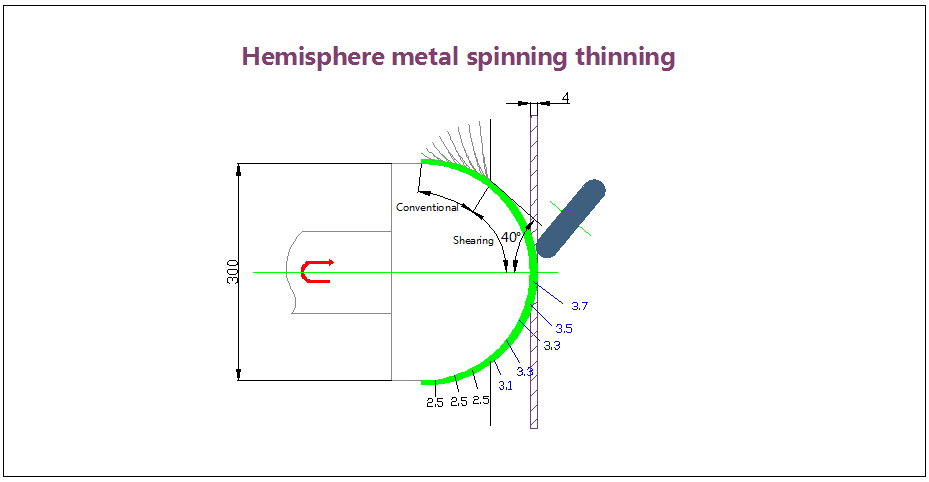

④ Hemisphere metal spinning thinning

Hemisphere spin forming needs shearing and conventional spinning, when the angle is bigger than 40º, this curve can be made by shearing, then using the conventional spinning to spin the rest.

Hemisphere thinning is different in different position, you can look the image above. The shearing position is gradually reduced the thickness that is marked by blue. The conventional is uniform thickness that is marked by black. Such as we use the blank thickness is 4mm, the diameter is 300mm, the actual thickness after spinning is like the image show.

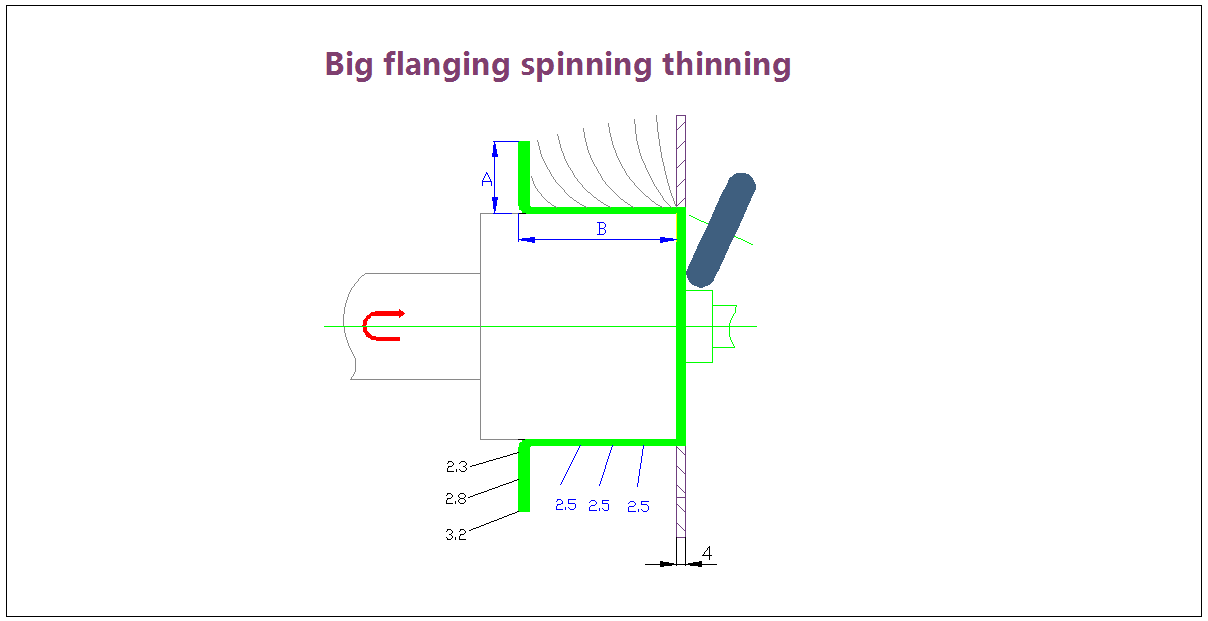

④ Hemisphere metal spinning thinning

The A or B value is bigger, the big flanging spinning thinning rate is bigger. The thinning rate of B position is bigger than A position, the A position is flange, the thickness is gradually increasing from the Min diam to Max diameter.

How to increase the spinning thickness

① Adjustting the CNC path>>, choosing bigger diameter roller or using the back path.

② Choosing the thicker blank thickness.

③ Increasing the spindle speed and feed speed.

④ Choosing single roller instead of double roller.

Recommended

- -Estimation of the blank diameter or thickness of spin forming

2025-04-26 - -A complete guide of CNC metal spinning machine

2025-04-06 - -Aerospace components-Precision manufacturing of CNC spinning

2025-01-29 - -How to improve the surface quality of CNC spinning

2025-03-06 - -Spin forming expert ▏Eight important metal spinning forming knowledge

2025-03-05 - -What is CNC metal spinning machine tool

2024-08-15 - -Metal spinning materials

2024-04-14 - -How to design a CNC metal spinning mold | mandrel

2024-04-12 - -Metal spun products - what product spin forming can do

2025-01-24 - -How to choose a CNC metal spinning machine

2024-04-18