Metal spun products - what product spin forming can do

Many metal thin wall parts of rotary body is made by spin forming. Compare to other metal forming process, such as deep drawing and expansion, metal spinning advantage is obvious. At first, the mold cost is cheap and the mold period is short, when customer have some design change, it is easy to repair the mold. Second, the material cost is less, spin forming haven't blank holder materail waste. Third, hot spinning can process harder metal.

Even though metal spinning have so many advantages, some people are confused that what product is mady by spin forming commonly, this article will introduce the basic and classic metal spun products in the different industries.

1. Lampshade

2. Tableware

3. Venturi

4. Industrial fan

5. Table base

6. Stainless steel funnel

7. Container

8. Oxygen and hydrogen Tank

9. Air spring shell

10. Turbojet

11. Military part

1. Lampshade

Manual spinning is applied in lampshade early, because all the lampshade thickness is thin, it is easy to spin by hand force.

Cost and advantage : Lampshade shell is commonly made by spin forming, except the mold cost is cheaper than deep drawing (hydraulic forming), it can forming more complex shape, higher height. On the other hand, it can finish metal forming , trimming , hemming on a mold, the production reduces the feeding and blanking labor cost. But deep drawing need more steps and mold to fish these fabrication. So metal spinning has the shorter sample lead time and less production cost.

Technical requirement : Many lampshade shell (reflector) have requirement that interior surface must be smoother and brighter. If you make the mirror polishing on Cr12mov metal Spinning mold, the aluminum spinning can achieve the mirror effect on the interior surface. Most of lampshade fittings and shells are used the aluminum and mild steel as the blank materials, these materials is cheaper than stainless steel. On the other hand, the aluminum has good ductility and heat dissipation, it is benefit to reduce the lamp heat.

2. Tableware

Cost and advantage : deep drawing have obvious advantage in production efficiency of tableware, most of tableware are made by stainless steel, stainless steel is hard to spin by manual spinning as the tensile strength valve is big. The exterior surface of deep drawing is easy to polish, metal spinning have uniform spinning line on the exterior surface, it needs more polishing cost to remove it. So the order quantity is more, deep drawing is better choice than metal spinning.

When the customer needs to customize the order that quantity is relatively small and the dimension is large, spinning mold cost is cheap, many customer choose metal spinning to process the customized tableware.

3. Venturi valve and venturi

What is venturi valve : Venturi value is a device to control the air pressure and flow in the negative pressure laboratory.

Cost and advantage : Venturi value commonly have four specification, diameter is 200mm, 250mm, 300mm, 360mm. It needs rolling a thin wall of cylinder, then using automatic welding to weld and make a tube (hand welding strength is not stable will cause the break in the welding position after spinning ), at last put the welding tube in a tube metal spinning machine to make necking and form the shape.

Deep drawing can't process it as the height of venturi is over 500mm, tube spinning is the good choice to form the metal spinning part that the height is over 400mm.

4. Industrial fan

Industrial fan can be used in wall, roofs, tunnels, it improve the air environment by outputting stronger airflow when it work.

Cost and advantage : Most of the diameter industrial fan is over 300mm and the order quantity is less than 300 pieces. If you form it by mold, the mold cost is expensive. Now metal spinning can forming the industrial fan by no-mold technology, the mold cost is very cheap.

Technical requirement : no-mold spin forming technology is widely applied in industrial fan, it reduce 80% mold cost and mold store cost . The backing roller the make the flange flat, the interior mold support the sheet and turn with the spindle. Now OKay machine can make the holes on the CNC metal spinning machine directly, you can't need to make laser cutting or stamping to make the holes any more.

5. Table base

Cost and advantage : metal table base are spun by stainless steel 304 or mild steel, the diameter is about 500mm, if you use the deep drawing, the mold cost is 3-5 times of metal spinning mold.

Technical requirement : table base are required to polish after spinning, the exterior surface will be smooth and reduce the polishing cost.

6. Stainless steel funnel

Stainless steel funnel is used in dring machine and filling machine, stainless steel 304 and 316 are food grade material. There are two ways to make stainless steel funnel, first ways is to make funnel by rolling a cone then welding, second way is to make funnel by metal spin forming.

Cost and advantage : rolling and welding a cone will have the welding line, this welding line is hard to polish, but metal spinning can make funnel without welding, the surface is smooth and easy to polish, the polish cost and material cost of metal spinning are cheaper than rolling and welding. The disadvantage is spin forming needs to make mold.

Technical requirement : most of stainless steel funnel surface finishing is brushed, metal spun funnel can achieve better brushed effect, some stainless steel funnel that is applied in medical equipment, the interior surface need to polish 6K mirror, it is hard to achieve this effect by other metal forming ways.

7. Container

There are many different metal container required in the factory, it can put coffee, milk , medicine, chemical liquid.

Cost and advantage : little size of stainless steel container(height <200mm)and aluminum container can made by deep drawing then necking metal spinning without welding. But large size stainless steel container (height >200mm ) needs to make by rolling and welding. rolling and welding a cone will have the welding line, this welding line is hard to polish, but spin forming can make funnel without welding, the surface is smooth and easy to polish, the polish cost and material cost of metal spinning are cheap than rolling and welding.

Technical requirement : most of stainless steel funnel surface finishing is brushed, metal spinning can achieve better brushed effect, some stainless steel funnel that is applied in milk bucket, the interior surface need to polish smoothly, otherwise it is hard to clean in the welding position.

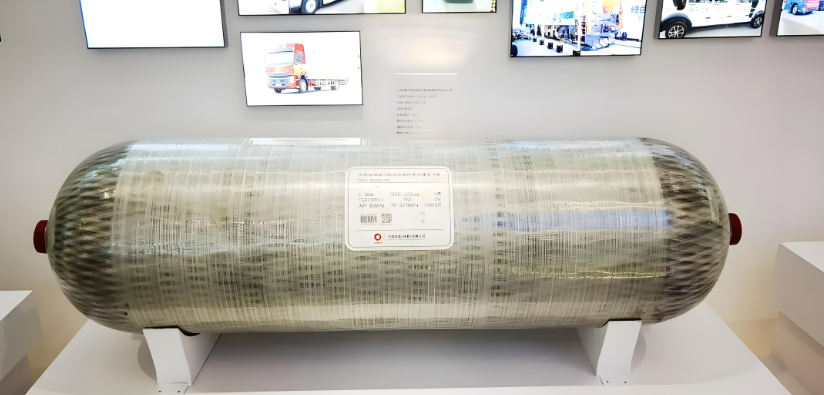

8. Oxygen and hydrogen Tank

Hydrogen tank : it is used to store the hydrogen, it is applied in auto full cell and rocket propulsion.

Oxygen tank : it is used to store oxygen, it supply oxygen to patients in hospital and climbing or diving peoples in exercise outdoors.

Cost and advantage : oxygen and hydrogen tank are make by aluminum 6061, this kind of material has good tensile strength compare to other aluminum materials. At the same time, the aluminum has lower density and aluminum tank is lighter, all the tank store air and it needs to bear the high pressure, so the air pressure testing is important in the production.

The blank of Little oxygen and hydrogen is a tube make by aluminum profile or aluminum forging , then using the necking spinning to make edge with heating, heating can make the materials flow easily and fastly in the metal spinning process, The thickness will be thicker after spinning .

Technical requirement : because the tank needs to bear high pressure after storing the air. metal spinning can make the tank without welding, if you use the welding to make tank, the tensile strength is not enough in the welding position.

Tank needs control the thickness in the process. At firt, you need to control the blank thickness of aluminum profile and forging. Second, Spin forming needs to control the thickness accuracy after necking. The thickness effects how many air pressure valve the tank can bear. Of cause, the hydrogen tank will be wrapped in carbon fiber in the final, it will improve the tensile strength of tank greatly.

9. Air spring shell

Air spring is a device used by a car to reduce vibration when passing through uneven roads. Air spring device are used the luxury brand of car, such as Mercedes, Audi, BMW, Porsche that the price is over 40,000 dollars.

Product category : there are many kinds of air spring housing in auto, each brand of luxury car is different. Such as Audi A6 and A8 have the different specification of air spring.

Technical requirement : the exterior housing is assemble with the plastic air bag, the tolerance is about 1mm can achieve the requirement. But interior housing is assemble a air cylinder, this air cylinder will move reciprocating motion along the interior housing, so the interior housing needs 0.1mm diameter tolerance to achieve mechanical property.

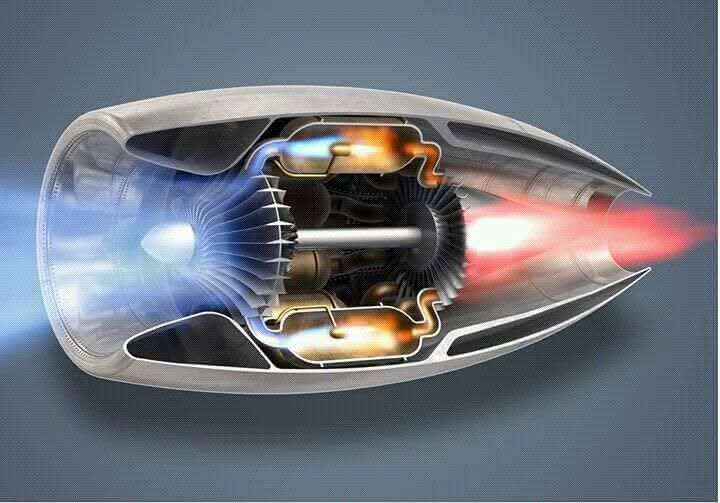

10. Turbojet

Turbojet is a type of turbine engine, It is characterized by complete reliance on the gas flow to generate thrust. Often used as power for high-speed aircraft.

Combustion chamber and nozzel are the basic components of turbojet. The material of combustion chamber is high temperature alloy(HASTELLOY), it can bear 2000ºC temperature, the material of nozzle is Inconel 625 and Inconel 718(nickel alloy ), these are high strength and high fatigue resistance alloy, ductility and toughness remian high, though it can’t be cold spinning.

Metal spinning advantage : except metal spinning mold is less, metal spinning shearing can make blank thinning and grain refinement, it improve the tensile strength. You can make a testing in the same condition, the metal is made by deep drawing, metal spinning, CNC turning, you will find that the metal spinning can work steadily in high temperature environment, because the tens strength of metal spinning part reduce 10-30% with the temperature rising, but CNC turning and deep drawing part will reduce 40-60% when temperature is high.

Technical requirement: combustion chamber and nozzle needs high precision after spinning, at same time, you also need to control the tolerance of thickness. If the tolerance of metal spinning parts are not qualified, it can’t be assembled in a welding fixture. If the gap between metal spinning part and welding fixture is too big, the welding thermal deformation is hard to control. All the high temperature alloy sheet are made by hot spinning, the metal spinning accuracy is hard to control than cold spinning.

How to control the accuracy of metal spinning >>

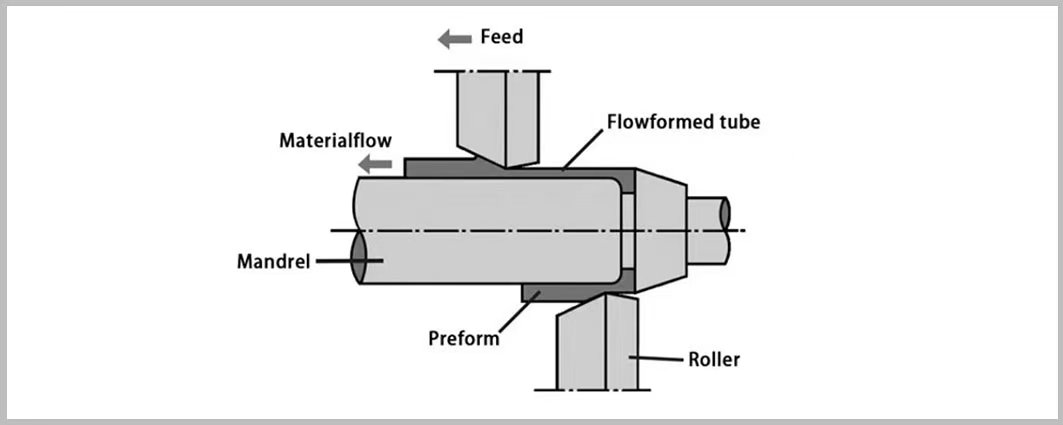

11. Military part

Many military parts needs three roller flow forming to make, Such as big hydrogen tank used in rocket, missile shell, compare to traditional CNC turning process, three roller flow forming can save the material cost, the tensile strength is improved after cold pressing.

Advantages : three roller is a special flow forming machine to make the long and deep cylinder part, traditional sheet metal can spin too long as the ductility of blank sheet is not enough, the blank material of three roller spinning is a tube, it can make the blank thinning and lengthen.

Except the metal spun products we introduce above, you can find metal spinning play a key role in the manufacturing, such as auto wheel shearing spinning, vertical pulley split spinning, head in pressure vessel. These are made by metal spinning, aerospace technology has been greatly developed with the rapid development of spin forming technology. There are more and more metal spinning companies have the ability to make the precision metal spinning products in the future.

Recommended

- -Estimation of the blank diameter or thickness of spin forming

2025-04-26 - -A complete guide of CNC metal spinning machine

2025-04-06 - -Aerospace components-Precision manufacturing of CNC spinning

2025-01-29 - -How to improve the surface quality of CNC spinning

2025-03-06 - -Spin forming expert ▏Eight important metal spinning forming knowledge

2025-03-05 - -What is CNC metal spinning machine tool

2024-08-15 - -Metal spinning materials

2024-04-14 - -How to design a CNC metal spinning mold | mandrel

2024-04-12 - -Metal spun products - what product spin forming can do

2025-01-24 - -How to choose a CNC metal spinning machine

2024-04-18